Service and repair of Lely robots

Lely milking robots are one of the most efficient solutions for modern dairy farming, but like all advanced machines they require ongoing maintenance and troubleshooting. If your robot starts displaying error messages, experiences sensor issues or has vacuum and milk leaks, it can quickly affect both performance and cow well-being.

Refurbished Lely Spare Parts: Save money without compromising on quality

When it comes to Lely milking robots, we know how important it is to use quality spare parts. But we also know that new original parts can be a big budget item. That's why Milcotec offers refurbished Lely spare parts - original parts that have been reconditioned and quality tested to work like new, but at a much lower price.

Buy Used Parts and Support Forests

Now you have the opportunity to support forests!

Did you know that used and refurbished spare parts can be just as good as new and at the same time used parts have a significantly smaller impact on the environment than similar new parts.

Milcotec COVID 19 status

At Milcotec we take the situation with COVID-19 virus outbreak seriously. We do our best to prevent any potential risks and effects on Milcotec employees, our families, customers and business partners. We follow the guidelines from Danish authorities and have taken all the recommended steps as a socially responsible company.

Annual area cleanup day

Our annual cleanup day went really well this year, approx. 130 kg. trash and plastic collected in 2 hours!

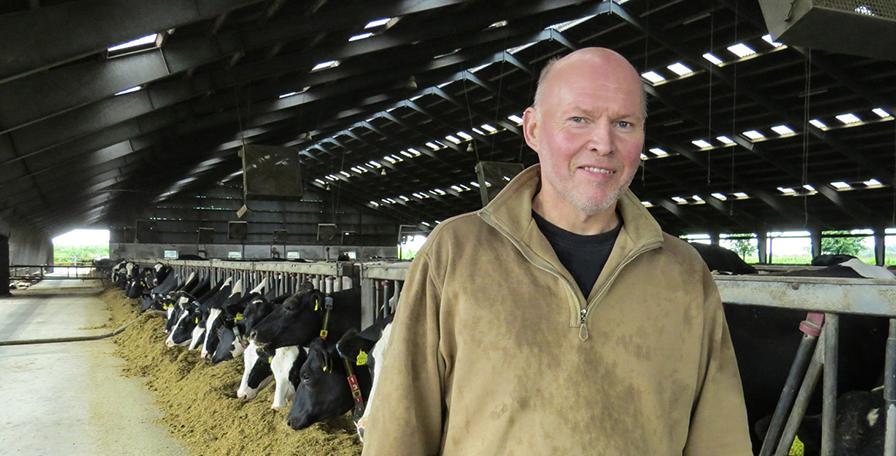

Good, stable milking worth its weight in gold

A Southern Jutland dairy farmer got rid of two worn-out milking robots and replaced them with a used Mobistar milking system from Dairy Systems Danmark. It soon brought an increase in yield. Good, stable milking is worth its weight in gold! Dairy farmer Gerrit Damsteegt, 30, of Marinusminde Farm in Nørre Vollum near Bredebro, can attest to that.

Leasing two milking robots and saving liquidity

Henrik Hansen, a newly established milk producer near Gram, took over two worn-out milking robots that were too expensive to maintain. They have now been replaced with two used, refurbished Lely A2 milking robots, leased from Milcotec at a fixed rate that also includes spares, consumables and service parts.

Milcotec gets milking robots working in Sweden

A week after Milcotec’s service engineers first visited a Swedish dairy farm with robot milking, the number of daily milkings had risen from 1.7 to 2.4 per cow. And the cell count, which had been above 500,000, had begun to come down.

‘It takes no more than 4½ hours for Milcotec to get here’.

Low-cost milking in outdoor Mobistar milking parlour

At Tage Lausten’s farm in Loegumkloster, one worker milks 430 cows in 5 hours in a used Mobistar milking parlour with 12 clusters. ‘The Mobistar was cheap to buy and works really well in every way’, he says. Milking many cows does not necessarily require expensive, advanced equipment in order to work well from day to day - as Tage Lausten of Øster Terp near Løgumkloster can confirm. His total of 1,200 Holstein dairy cows live on two farms 5 kilometres apart.

Where the milking clusters are flushed after each cow

Milking is done three times a day at Grambogård, and it takes around 3 hours each time to milk the 430 or so dairy cows currently in the herd with 32 milking clusters – including start-up and cleaning.

Christian Stenskrog opted to have the DairyMaster milking plant fitted with the ClusterCleanse flushing system, as a lot of cows were to be bought from various herds for the expansion.

Login

Register